Dr. Leirs, Belgium: Optimizing a high throughput OR for robot-assisted knee surgery

This is the second case study of our case series with Dr. Geert Leirs, leading orthopedic surgeon at Noorderhart Mariaziekenhuis Hospital in Pelt, Belgium. This article outlines how Dr. Leirs took additional steps to further optimize his high throughput OR for robot-assisted knee surgery, based on DEO.care’s insights. Dr Leirs’ story demonstrates how embarking on a continuous improvement journey will benefit the patients, hospital and entire OR team, even in a high-throughput, highly standardized environment.

In the first article, we shared how Dr. Leirs implemented lean principles to transform his OR for robot-assisted knee surgery into a high-throughput environment. His key implementation strategies were: eliminating time and material waste, ensuring standardized and consistent processes and fostering team ownership and communication. Those efforts resulted in Dr. Leirs being able to treat six robotic knee replacement patients during a standard operating day, while ensuring optimal quality of care.

DIGITAL TWIN SIMULATIONS UNVEILED CONTINUOUS IMPROVEMENT OPPORTUNITIES

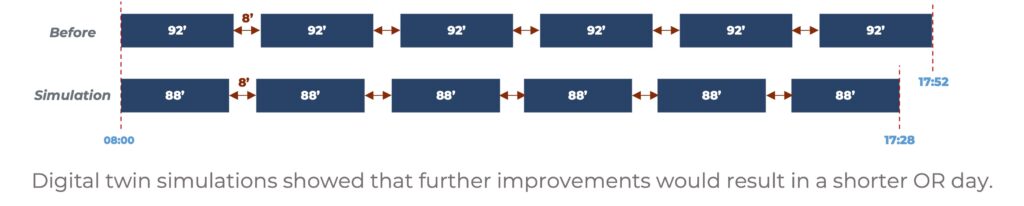

DEO.care performed measurements in Dr. Leirs’ OR to provide further data-driven opportunities for continuous improvement, aiming to optimize his OR processes even further. A digital twin simulation using DEO.care’s platform unveiled improvement opportunities in three areas:

- Optimization of material preparation flow: A further parallelization of material, patient and robot preparation processes would result in a reduction of the total preparation time, enabling the surgical team to finish the operating day earlier.

- Removal of redundant materials from instrument trays: During the analysis, it was observed that a number of instruments were not used during surgery. Removing redundant instruments would result in a reduction of the total instrument set.

- Adaptation of draping and disinfection technique: Benchmarked with DEO.care best practices database, an opportunity for ergonomics improvement for the surgical team was observed in the draping and disinfection processes. The OR team of Noorderhart successfully implemented this optimization, resulting in a reduction of the physical strain during the procedure.

The digital twin simulations displayed that implementation of the outlined improvements would result in shortening the duration of the total OR day.

RESULTS

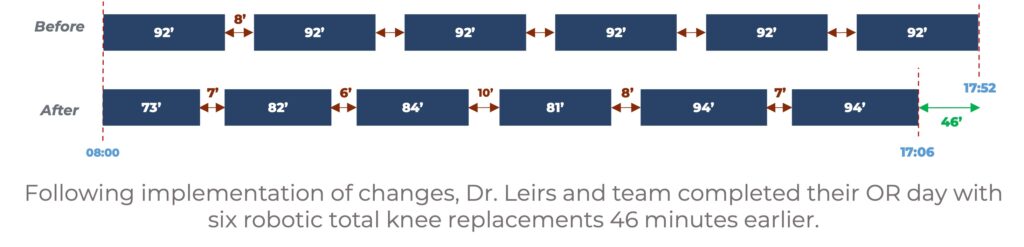

Led by Dr. Leirs, the surgical team took the suggestions to heart and started a stepwise implementation with successful results. The implementation demonstrated that the surgical team was able to:

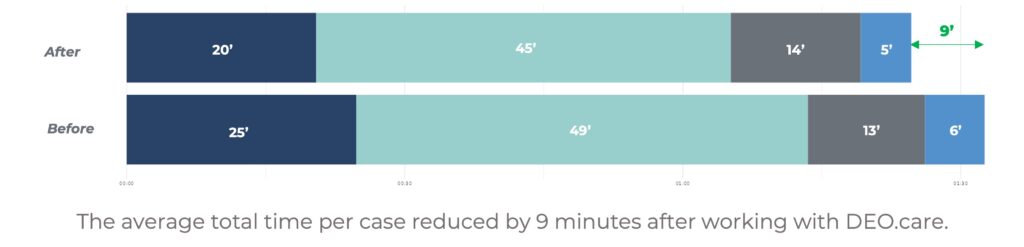

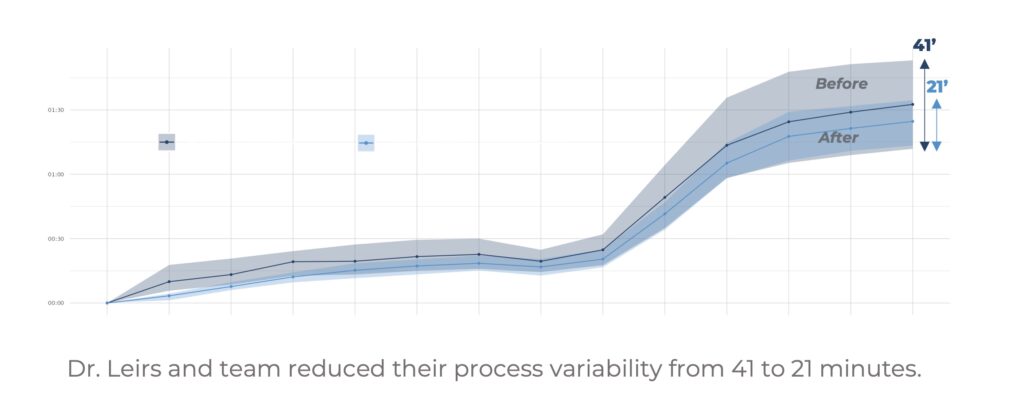

- Reduce their process variability from 41 to 21 minutes per surgery.

- Reduce the total OR time per surgery by 9 minutes, resulting in a shortening of the total OR day by 46 minutes.

- Optimizing ergonomics during disinfection and draping and reducing instrument sets from 9 to 7 trays also contributed to a shorter OR day, as well as reduced physical strain on the OR team.

THE IMPACT ON THE TEAM AND HOSPITAL

The OR team is supportive of the improvements Dr. Leirs continues to champion. Wouter Frusch, scrub nurse for Dr. Leirs’ OR team, comments: “What’s so great about working in this team is the teamwork. Because the processes are standardized, everyone is aligned, and the OR day runs efficiently and smoothly. I was astonished by the additional insights the data from DEO.care could deliver us; these were meaningful insights that allowed us to further improve each step.”

While Dr. Leirs persists in seeking continuous process improvements, he is now sharing his experiences with surgical teams across the globe, enabling them to optimize the implementation of surgical robotics into the OR. Dr. Leirs’ OR serves as a model for healthcare organizations that aim to implement surgical technologies, such as surgical robotics in an optimized way, thereby taking into account OR throughput, OR team wellbeing and optimal quality of care.