Dr. Sershon, United States: Increasing throughput in the ASC

This is the second article in our series about Dr. Robert Sershon, orthopedic surgeon at the Anderson Orthopaedic Clinic and renowned expert in anterior total hip replacement, total knee replacement and outpatient joint replacement.

Earlier this year, we shared Dr. Sershon’s insights on achieving an efficient process in his outpatient practice, visualized using data generated by DEO.care’s process digital twin. You can read it here.

Since then, to meet the growing patient demand at Harborside Surgery Center, Dr. Sershon has continued to work with DEO.care to optimize the use of available OR time without lengthening his day.

With a step-by-step approach of gathering and integrating insights into his current OR processes, Dr. Sershon has been systematically refining and standardizing his surgery workflow. In this second article, we discuss how Dr. Sershon and his OR team executed changes based on DEO.care’s data and process digital twin, resulting in a throughput increase from nine to ten joint replacement surgeries in an eight hour OR day.

Approach

Gather Data and Integrate Insights

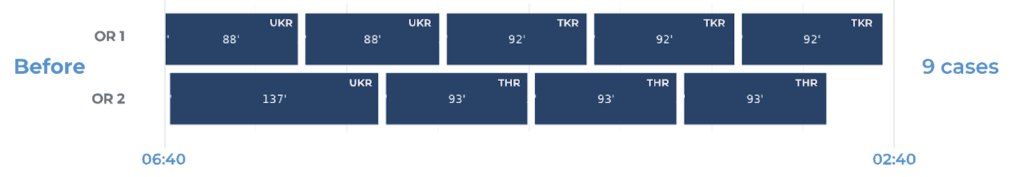

First, DEO.care conducted an operational excellence assessment, which included data generation, at the Harborside Surgery Center over two OR days. At this time, Dr. Sershon and his team were performing nine joint replacement surgeries in a standard eight-hour operating day across two ORs, as shown in Figure 1 below.

Then, DEO.care provided Dr. Sershon and his team a detailed insights report, which unveiled opportunities to improve preparation parallelization, optimizing efficiency of the OR process flows without compromising quality of patient care. The OR team almost immediately began implementing small changes outlined in the report.

Focus Efforts with the Help of a Process Digital Twin

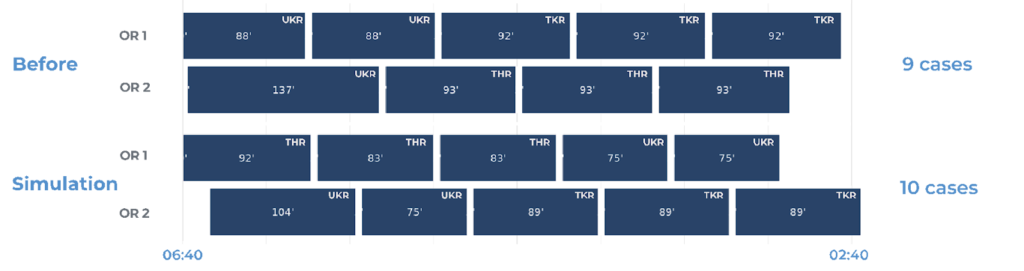

Process digital twin simulations based on baseline measurements demonstrated the opportunity for improvements in operational flow, resulting in reduced total OR time and decreased process variability. The simulations showed that by parallelizing patient and material preparation processes, as well as reducing idle times in the preparation processes, Dr. Sershon and his team would be able to go from nine patients to ten patients in parallel ORs.

Based on the simulated options to achieve the goal of increasing OR throughput by one case per day, DEO.care facilitated a workshop to help manage change effectively. The team discussed specific process changes and made collaborative decisions to ensure the proposed implementations were feasible and acceptable for the entire surgical team.

Results

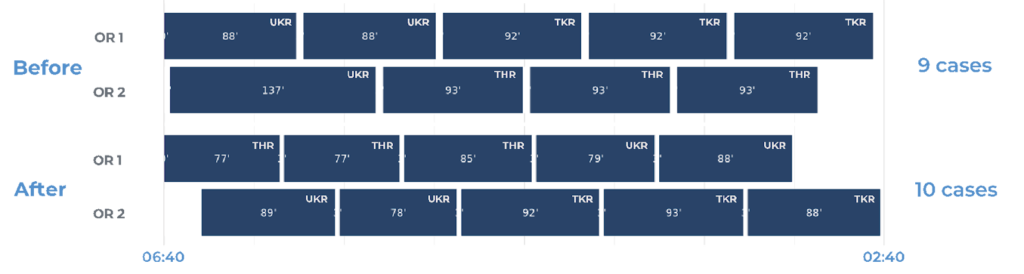

With this change cycle, it took just three months from measurements to implemented outcome. Following implementation of changes, DEO.care performed post-implementation measurements. The results demonstrated that Dr. Sershon and his team had successfully optimized their processes. The team is now able to perform ten joint replacement surgeries within the eight-hour day, increasing from nine surgeries, as shown in Figure 3 below.

Sara Redden, the OR Manager, was happy with the outcome. She stressed that despite adding one more case to their day, the team did not feel additional demands on their energy or time. The improvements recommended made things easier for the team and improved productivity at the same time, she added.

What’s Next?

The granularity of DEO.care’s data and actionable insights in the report enabled Dr. Sershon to improve his already efficient processes. Supported by a team that is committed to continuous improvement and operational excellence, Dr. Sershon will continue to optimize his OR process based on the latest available insights and process innovations.

Additionally, Dr. Sershon recognizes the importance of sharing the insights and learnings with other surgeons in his practice, so everyone can benefit from the effort of building optimal OR workflows at the Harborside Surgery Center.