Dr. Sershon, United States: Achieving OR Efficiency in the ASC

Dr. Robert Sershon is The Anderson Orthopaedic Clinic’s robotic joint replacement program pioneer and a renowned expert in anterior total hip replacement, total knee replacement, and outpatient joint replacement. In 2023, he performed over 700 joint replacements.

As patient volume grew in Dr. Sershon’s outpatient practice, he found ways to optimize his surgical processes through safely and expertly performing surgeries with the goal of increasing patient satisfaction and operating room (OR) efficiency. The progressive work environment cultivated at Harborside Surgery Center promotes continuous improvements and efficiency, while maintaining the balance between the surgical team’s workload and well-being. To optimize his processes, Dr. Sershon took the following approach:

- Standardize Steps

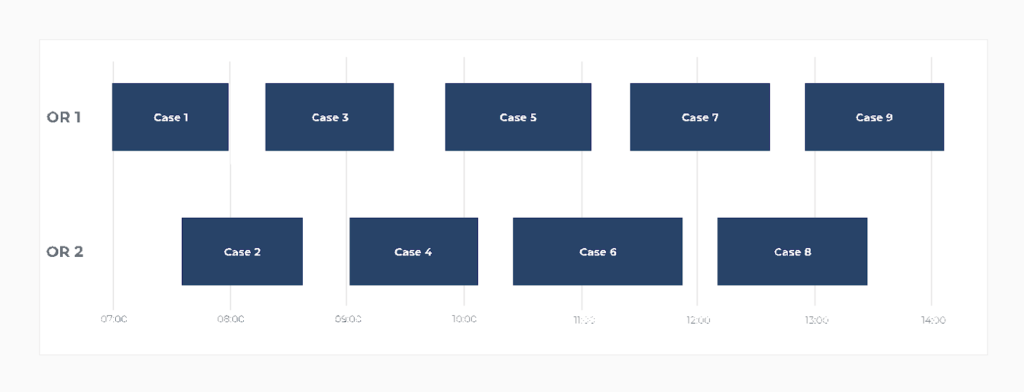

During his first year of practice, he focused on how to transition from working in a single OR to safely running two ORs in parallel. Over the span of nearly a year, Dr. Sershon systematically refined his processes to create a step-by-step, standardized surgery workflow. With consistent surgical steps and timing, the team was able to establish a predictable flow and daily routine.

- Become Consistent

Creating a systematic approach to each procedure resulted in the establishment of an efficient environment characterized by consistent case times and turnover. Dr. Sershon was then able to pivot to two ORs with relative ease. The culmination of his continued efforts and process refinements resulted in a typical practice day where Dr. Sershon conducts between 9 and 11 joint replacement cases across two parallel ORs.

- Set the Pace

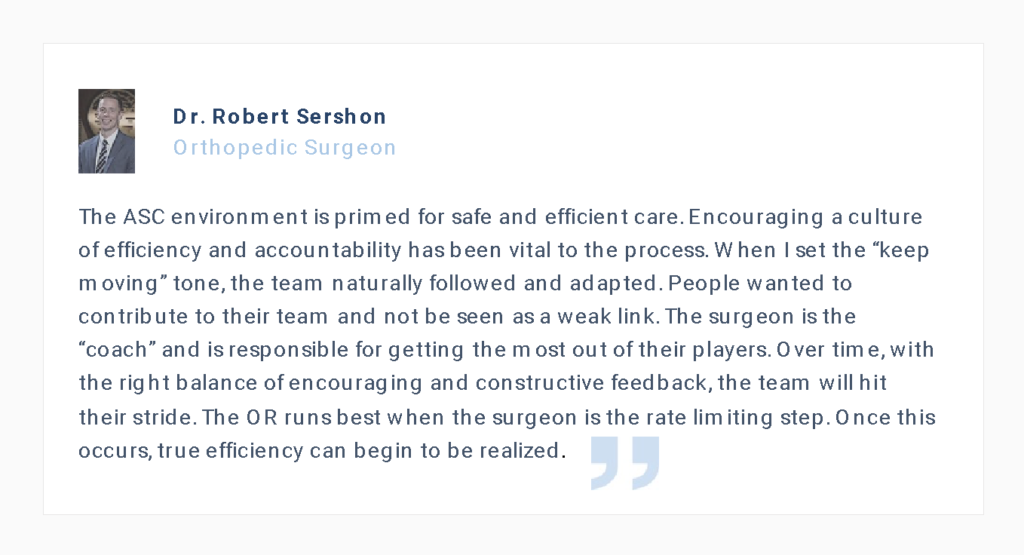

With this high daily throughput, it became important to minimize idle OR time. It was imperative for staff and the surgeon to have confidence the day could proceed and end as planned. To help accomplish this, Dr. Sershon established the working cadence in his OR by setting the fluid pace of the day himself. The team naturally adapted to this tempo to limit idle OR time, all while fostering a culture of mutual respect and accountability. As a result of this team environment and stepwise refinement process, Dr. Sershon has found that he is now the rate limiting factor as it pertains to efficiency during a typical OR day.

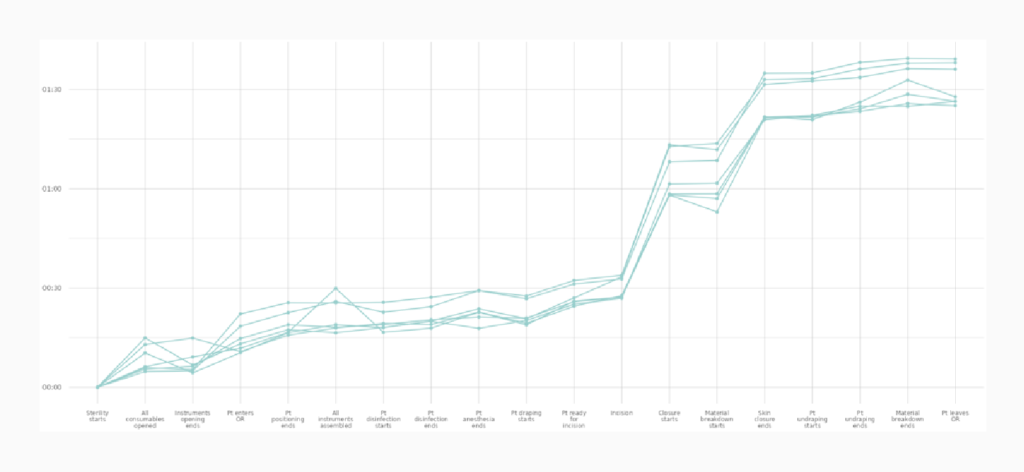

Dr. Sershon believes his OR is in the early stages of their journey. Using DEO.care’s process digital twin, he is able to leverage a data-driven approach towards operational excellence in his OR. The rich and granular data generated is a great way to align all stakeholders within the OR and organization as it provides an unbiased and objective basis to discuss best practices and opportunities for improvement.

“Data gives an objective measurement of where our process is right now and provides a roadmap for where we want to be,” says Dr. Sershon. “I believe this deep understanding of data is crucial to promote continuous growth and improvement.”

Dr. Sershon’s journey towards optimizing efficiency in the ASC reflects his commitment to providing high-quality patient care while respecting his team’s well-being and workload. By embracing fundamental principles and leveraging innovative solutions like DEO.care’s AI-backed digital twin technology, Dr. Sershon continues to drive operational excellence in surgical practice, setting a benchmark for efficiency and quality in outpatient joint replacement procedures.