Dr. Leirs, Belgium: Streamlining the OR for Robot-Assisted Knee Surgery

This case study delves into how Dr. Leirs, leading orthopedic surgeon at Noorderhart Mariaziekenhuis Hospital in Pelt, Belgium, implemented lean principles to transform robot-assisted knee surgery and increase OR throughput.

Robot-assisted knee surgery is not only a technically demanding procedure for the surgeon and his/her team, but also is often thought to be more time consuming and stressful, resulting in a negative impact on efficiency, and throughput.

Dr. Leirs is renowned for his expertise in robot-assisted knee surgery and was one of the early adopters of robotics, performing 250 robotic procedures annually. Recognizing the need to streamline processes, he embarked on a journey to implement lean principles to optimize his procedures, aiming to enhance efficiency, consistency, and reproducibility with minimal variability while maintaining optimal quality of care. His goal was to establish clear and easily understandable processes that remained consistent with rotating nursing teams, ensuring smooth surgeries despite continuous changes in personnel.

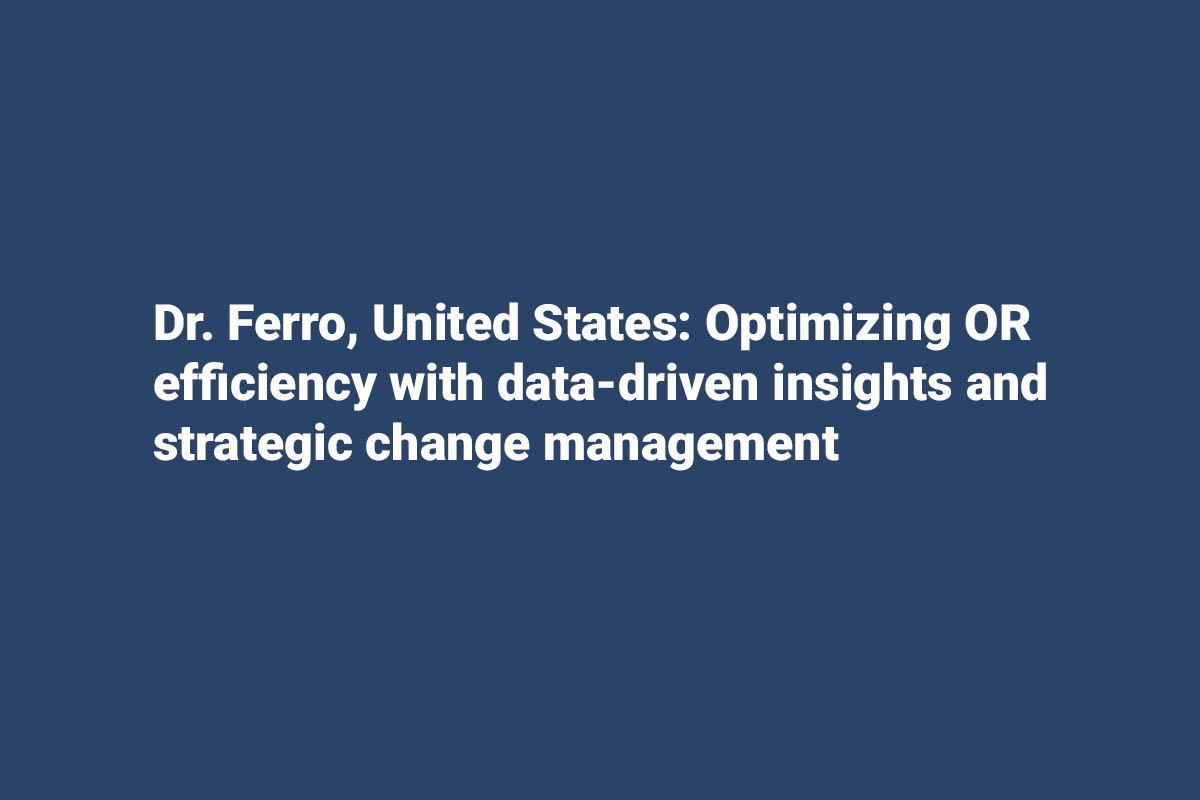

Together with DEO.care, Dr. Leirs conducted a comprehensive study with the intent of mapping his OR processes and best practices, demonstrating how leveraging lean principles can help to streamline robot-assisted knee surgeries and optimize operational efficiency. The data confirmed a very consistent implementation of processes, with minimal variability and waste, across multiple rotating nursing teams, as shown in Figure 1 below.

Figure 1: Process variability in preparation phase across all surgeries observed

Dr. Leirs implemented the following key strategies to streamline robot-assisted knee surgeries, and achieve operational excellence in his OR:

Elimination of Time Waste:

- Lean principles guided the elimination of time waste through the development of a clear, step-by-step format for Robot Assisted knee procedures.

- Parallelization of robotic, material, and patient preparation processes minimized downtime and optimized workflow.

Elimination of Material Waste:

- Elimination of instruments that are not being used from trays and optimizing tray configuration reduces preparation time, breakdown time and reduces task complexity for the surgical team.

Standardization and Consistency:

- A standardized procedure format ensured that every surgical team member understood his or her role and responsibilities, leading to efficient, consistent, and reproducible robot- assisted knee surgery processes.

- Process data collection and analysis demonstrated high consistency across all robot-assisted knee procedures, with minimal variability in OR time, preparation time, breakdown time, and turnover time.

Team Ownership and Communication:

- Ownership of tasks was distributed among surgical personnel, fostering accountability and ensuring smooth execution of procedures.

- Consistent communication between team members, including the surgeon, anesthesiologist, circulating nurse, and scrub nurse, facilitated seamless coordination throughout the procedure.

Results

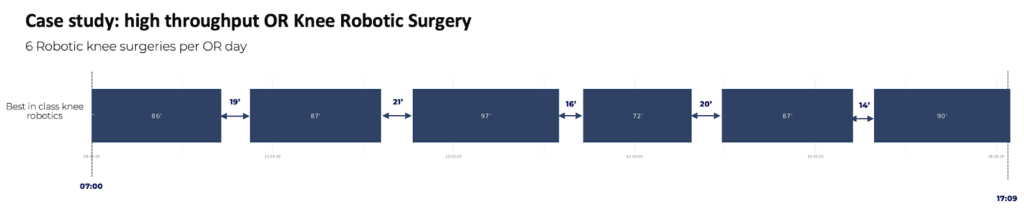

Dr. Leirs successfully streamlined his procedures, increasing throughput gradually to six robot-assisted knee surgeries per day, as shown in Figure 2 below. His dedicated efforts enabled him to achieve those results, while working with rotating nursing teams.

Figure 2: Day overview of a typical surgery day of Dr Leirs with six robot-assisted knee surgeries

Lean principles facilitated the achievement of significant improvements in operational efficiency, as well as consistent and reproducible outcomes, with minimal variability in key process metrics. The adoption of standardized processes and consistent communication fostered a culture of excellence, enabling high throughput without compromising quality.

The standardized robot-assisted knee procedure blueprint developed by Dr. Leirs is now adopted by the entire knee team of Noorderhart Hospital, benefiting multiple surgical teams and surgeons. It also serves as a model for healthcare organizations seeking to optimize complex surgical procedures using lean methodologies.

“I am convinced that when surgeries are performed with streamlined processes, this will ultimately benefit patient care and l positively impact the patient’s experience.”