Dr. Luc Vanlommel, Belgium: Unleashing the Power of Data with Robot-Assisted Surgery for a High Throughput OR

While robot-assisted surgery has the potential to revolutionize operating rooms with improved surgery precision and patient outcomes, introducing and integrating robotic devices into OR workflows can be taxing on surgery teams. Orthopedic surgeon Dr. Vanlommel effectively introduced and applied robotics to his OR without sacrificing throughput. Now, in an effort to ultimately achieve the quadruple aim, he works with DEO.care to:

- Further standardize processes across teams;

- Continuously improve process efficiency, financial performance, and team well-being; and

- Optimize instrument usage.

Challenge

Dr. Vanlommel and his team faced the challenge of integrating robot-assisted surgery (RAS) for knee replacement into their existing OR workflow, replacing conventional surgery. Introducing new technology like robotic devices often creates disruption to current workflow within the OR, and as a result, the total duration of surgery can increase, thus reducing throughput. The introduction of this advanced technology required overcoming a learning curve and ensuring a smooth transition for the entire surgical team.

Solution

Dr. Vanlommel emphasized the importance of minimizing disruptions to the OR’s processes, while developing an optimal workflow for knee RAS. Examples of best practices to achieve this include:

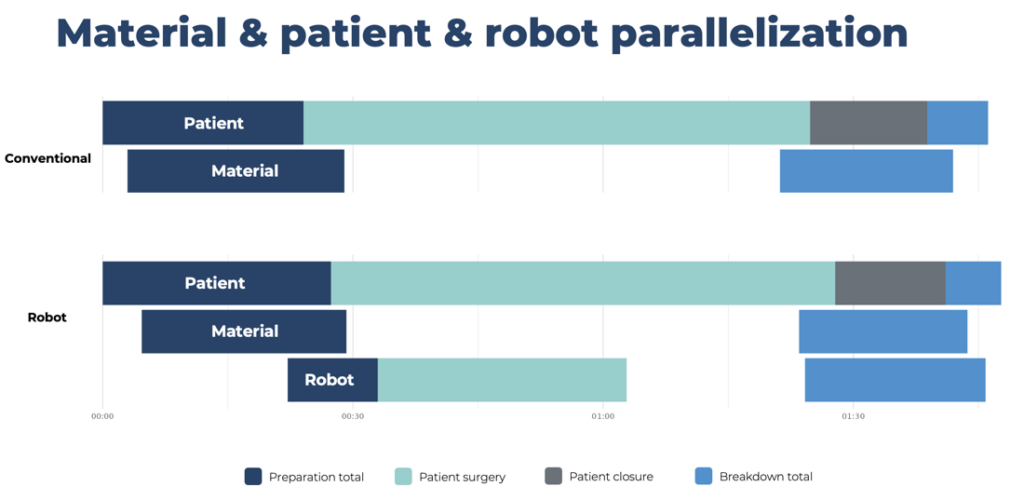

- Evaluate the preparation and breakdown processes of the robotic device to understand how best to fit preparation and breakdown into your current workflow. This includes identifying steps that could occur during patient turnover, which significantly reduces idle time, as well as tasks that can be completed concurrently.

- Identify processes that can run in parallel to minimize overall OR time per patient without compromising the quality of care. For example, the surgery team can prepare the instrument table, disinfect and drape the patient, and drape the robotic device concurrently with other preparatory tasks, reducing the overall time spent in the OR.

Figure 1: Process parallelization allows the surgical team to work in an optimal way.

- Consider your entire surgery team and allow time for their learning curve. Surgery teams will not reach the same OR throughput from day one of implementing robotic devices, but over time processes will become increasingly more efficient. From the beginning of when robotic devices are introduced, involve the entire surgical team, including anesthesiologists, OR staff, leadership, management, circulating nurses, and scrub nurses. Offer theoretical and practical (process and clinical) training and introduce robotic devices gradually.

- Commit to continuous improvement. DEO.care supports Dr. Vanlommel’s use of RAS technology with operational excellence using digital twin technology. DEO.care is performing measurements in his OR at regular intervals, post implementation of the robotic devices. We are providing comparative insights reports with baseline metrics, and best practices, to drive consistency across surgical teams and support continuous improvement.

By using DEO.care’s AI-driven data and insights platform, including process digital twins and the instrument usage analyzer, Dr. Vanlommel and his team now have a foundation to make data-driven decisions together. They can analyze differences in workflow between surgeons, identify specific areas for fine-tuning or additional improvements, optimize instrument tray configurations, and further streamline processes, benefiting both circulating nurses and the surgical team, while ensuring the highest quality of patient care.

“Having the data and insights from DEO.care allows us to further streamline our processes across surgeons and surgical teams.” – Dr. Vanlommel

Results

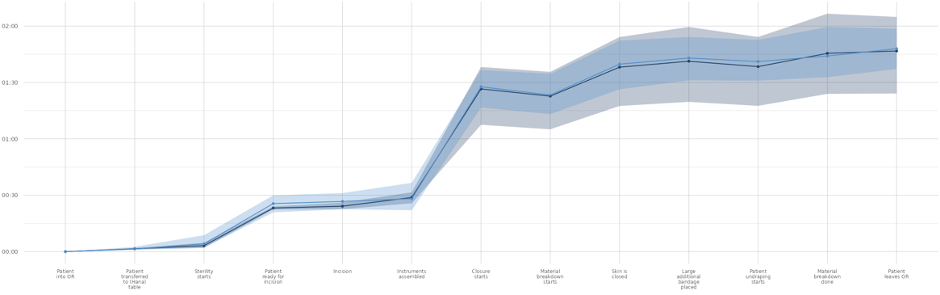

The surgical team initially faced challenges during the learning curve, requiring patience. However, once the optimized workflow was established, the team found that the robotic devices facilitated more efficient workflow and accurate work, reducing the need for intraoperative corrections and implying a potential reduction in surgery time.

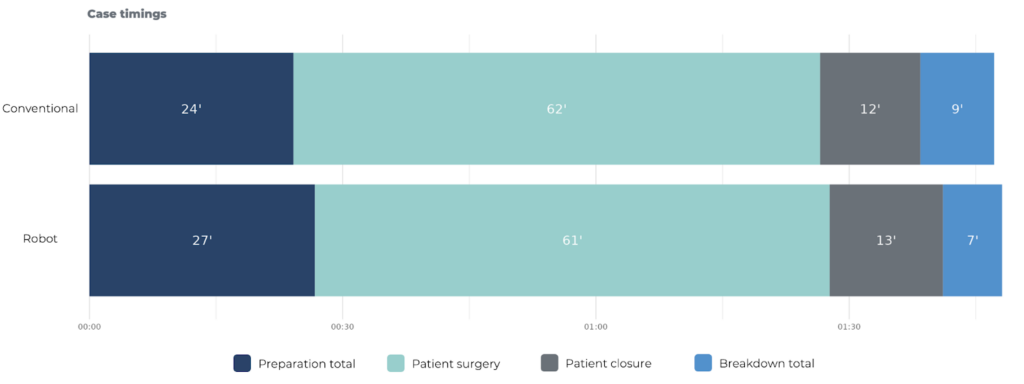

The implementation of knee RAS did not impact the daily capacity or the number of patients treated per day, as the operating time remained the same for total knee procedures.

Figure 2: Process consistency of executing knee replacement surgery with robotics (blue) vs conventional (gray)

Figure 3: Time comparison of executing knee surgery conventionally vs robotics-assisted: No difference in total time is observed (Dark blue: Preparation time, green: surgery, gray: closure, light blue: breakdown).

Dr. Vanlommel’s strategic implementation of knee RAS allowed his OR to achieve operational excellence, maintaining the same daily capacity while enhancing the overall efficiency and satisfaction of both the team and OR patients. His commitment to continuous improvement to achieve the quadruple aim is supported by DEO’care’s data-driven insights.

If you would like DEO.care’s support in measuring your OR’s efficiency and workflow through our annual subscription, schedule a call.