Professor Assaker, France: Increasing OR Throughput by 25%

Increased OR throughput can significantly benefit the healthcare system by shortening waiting lists and increasing the financial health of a hospital. Standardizing OR processes allows hospitals to increase throughput while maintaining optimal patient experience and quality of care and ensuring a healthy and sustainable work environment. Now, medical device companies are harnessing data-driven technology solutions to help their clients increase OR throughput—without increasing the burden on staff or compromising the quality of care—and achieve operational excellence.

BACKGROUND

Professor Richard Assaker wanted to optimize the use of the OR room at his center for spinal neurosurgery at the Institute François Calot. Medtronic IHS, the services & solutions department of Medtronic, partnered with DEO.care to combine their transformational expertise with DEO.care’s AI-driven data and insights platform. As such, it was the perfect match to help Professor Assaker increase his OR throughput for discectomy procedures. As a result, he was able to increase his throughput from four surgeries to five surgeries per day, achieving a 25% increase in throughput.

THE PROCESS

- Gather Data

Medtronic’s Integrated Healthcare Solutions integrated DEO.care’s platform within their offering to Professor Assaker, enabling him access to AI-driven data and insights. Medtronic IHS set-up the DEO.care remote measurement kit, equipped with a specialized camera app, to capture surgery data via anonymized videos. This allowed them to perform baseline measurements regarding the operational excellence of his operating room—in compliance with GDPR requirements — while maintaining the privacy and anonymity of the individuals. From there, DEO.care configured a virtual model of his operating room, also known as a process digital twin.

- Analyze Data

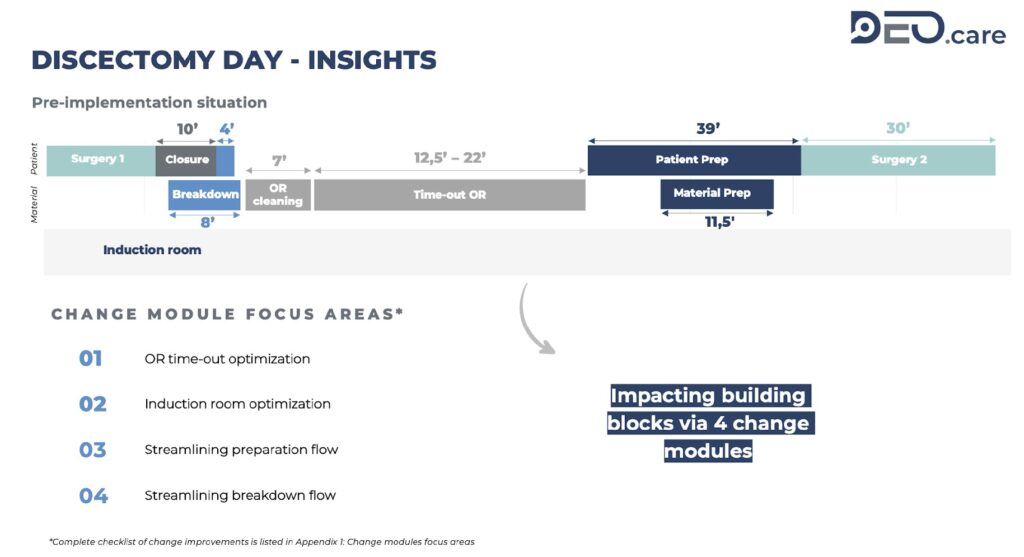

Once the process digital twin was created, DEO.care ran simulations and analyzed the current operating room procedure from start to finish. The analysis of this data revealed four change modules where they could increase the efficiency of the overall process by making adjustments to optimize the OR time-out and induction room procedures, and streamline the preparation and breakdown workflow.

Figure 1:Initial data revealed four potential areas of change to increase efficiency in the OR.

- Plan & Test

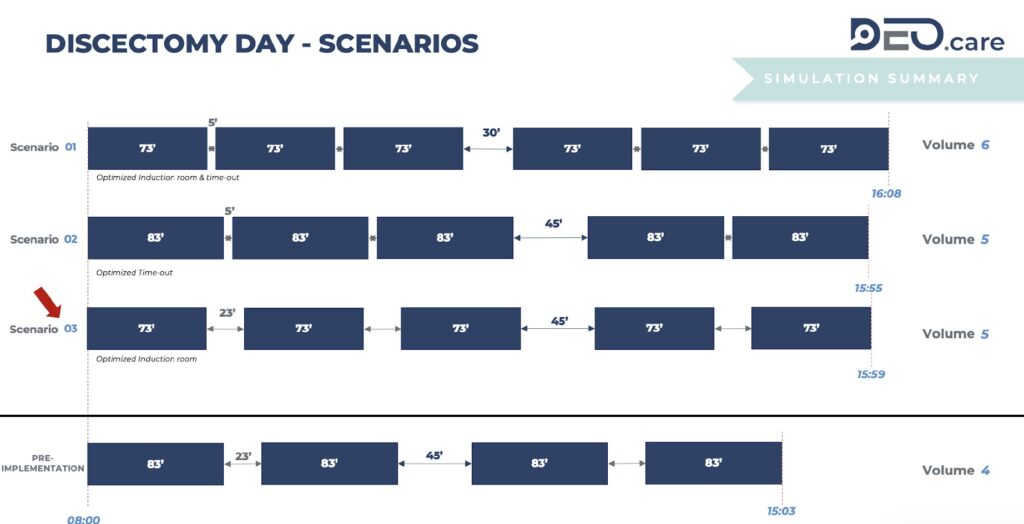

By testing changes within DEO.care’s data-driven simulation platform, Professor Assaker could take the burden of trial and error off his surgical team. The simulations identified OR time-out and induction as two areas with the highest impact on improving the OR processes, so they modeled three different scenarios to identify which approach to go for during implementation.

Figure 2: Pre-implementation, Professor Assaker was able to execute four discectomy procedures in one day (Bottom). By optimizing OR time-out in between surgeries (Scenario 2) or optimizing the use of the induction room (Scenario 3), the scenarios predicted Professor Assaker would be able to increase throughput with 25% to five procedures in one day. Combining both scenario 2 and 3 would eventually lead to a 50% throughput increase and 6 procedures in one day (Scenario 1).

- Implement & Assess

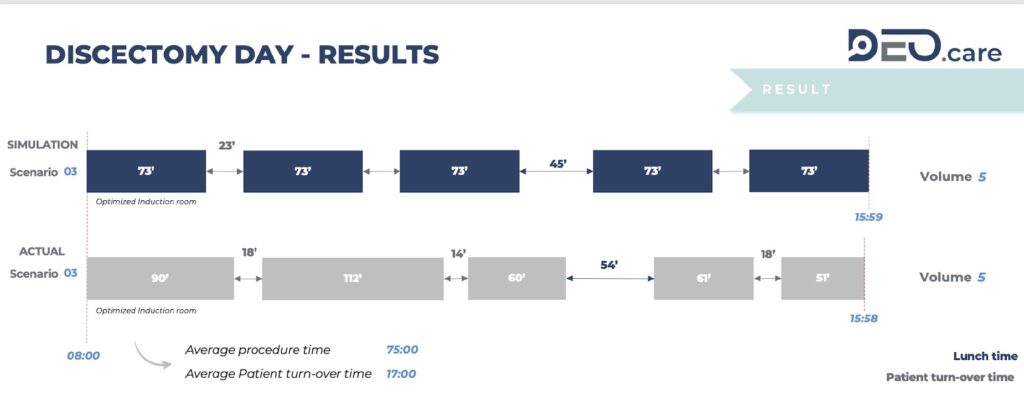

The surgical team in collaboration with Medtronic IHS then started to gradually implement the changes, rather than make any drastic moves to the team dynamics. After looking at the various scenarios, they decided to start with an initial goal to increase procedures from four to five per day by targeting induction room optimization. At the time, the Institut Calot was not consistently using an induction room to induce the patient. By utilizing a separate room for Induction, the patient’s preparation could start sooner, reducing the total OR time for one procedure from 83 minutes to 73 minutes. DEO.care provided a master Standard Operating Procedure to the surgical team, with the outline of the optimized processes and roles and responsibilities. An implementation day was organized, at which DEO.care executed follow-up measurements.

Figure 3: Professor Assaker implemented optimization of the induction room and was able to achieve five surgeries in one day, just as the simulations provided by DEO.care had predicted.

Upon completion of the changes, they were successfully able to add one additional surgery to their operating room workflow within the same period of work time. As a result, his team found their processes ran smoothly, increasing the overall satisfaction of the entire team, and at the same time the center was able to optimize their financial performance.

“I was skeptical going into this, but seeing the data has opened my eyes,” shared Professor Asssaker. “I’ve been able to increase my caseload without feeling an increase in my workload. As a surgeon we think we understand OR processes well, but we actually only see the actual surgery. What we don’t see is all the surrounding processes, such as the prep and breakdown. DEO.care and Medtronic IHS helped me unveil insights into all those processes. Data doesn’t lie.”

Thanks to Medtronic’s work with DEO.care, Professor Assaker has access to ongoing support through continual data collection and monitoring. This will enable him to continue to implement the next phases of changes identified, with the goal of incrementally moving to six surgeries per day. Professor Assaker is now hoping to expand the use of this technology to his surgical center at CHU Lille University Hospital.

Medtronic IHS continues seeing the benefits of using software solutions like DEO.care’s AI-driven data and insights platform to combine their operational and care pathway expertise with innovative technologies and help hospitals to achieve operational excellence and increase OR throughput.

“We learned a lot from DEO.care’s database of best practices from other hospitals they have worked with. The DEO.care process know-how made us realize we can further optimize our way of working, and gave us the tools and insights to implement this change. In the end, this will positively impact the entire surgical team.”

–Romain Bousdira, OR Manager at Institut Calot

“The DEO.care insights reports and documentation are clear and easy to work with—visual, tangible, meaningful, and impactful. The DEO.care way of working is very data-driven, customer-specific, objective, tangible. The DEO.care platform is a strong asset for the IHS consultancy team to bring more value to our customers and achieve with speed and accuracy our targets in terms of surgical outcomes and efficiency. ”

–Pauline Chevreau, Integrated Healthcare Solution Consultant, Medtronic

Do you want to know how we can help you get started? Schedule a 15-minute intro call. No strings attached.